HIGH TENSILE FENCE WIRE

A100 Longlife™ HT Wire, 12 1/2 gage, grade 180-205 HT wire with 1380 lbs. min (1570# max) breaking strength, 55 pounds and 2160' per coil, class 3 zinc, to ASTM A854. The expected number of years of use in a "humid environment" until rust first appears is 13 to 20.

A103 Longlife Plus™ HT Wire, 12 1/2 gage, grade 180-205 HT wire with 1380 lbs. min (1570# max) breaking strength, 55 pounds and 2160' per coil. Only MAX-FLEX Longlife Plus™ wire has an extra weight "class 4" type coating with 50% more zinc that lasts up to twice as long. The expected number of years of use in a "humid environment" until rust first appears is 20 to 30 or more.

A110 Superlife 14™ HT Wire, 14 1/2 gage, grade 180-205 HT wire with 820 lbs. min (940# max) breaking strength, 33 1/2 pounds and 2160' per coil, class 3 Superlife™ type of coating. Easy to handle and tie but just as strong as barbed wire - it is ideal for permanent electric fence and easier do-it-yourself installations. Expected years until rust first appears is 30 or more.

More Superlife™ Wire Information

Choose From Three Great Wires

MAX-FLEX™ high tensile wire is both strong enough for any smooth wire application and flexible enough to use knots for all connections. It is available with a Longlife™ and Longlife Plus™ class 3 or 4 zinc coating and a Superlife™ coating that protect two to three times longer. Coating life is much longer yet in very dry climates and only about half as long in coastal and industrial environments and when exposed to corrosive sprays and chemicals.

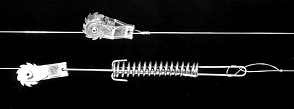

SPRINGS & TIGHTENERS

A220 Superlife™ Springs, heavy duty compression springs used for tension meters in all high tensile fences and for shock absorbers in most electric fences. MAX-FLEX springs have high tensile drawbars for extra strength and the most advanced wire coating available on the spring coils for the strongest and longest lasting fence springs.

A300 Spring-Clip™ Tighteners, permanent heavy duty in-line wire tighteners used with or without springs for maintaining wire tension for the life of the fence. The Spring-Clip™ Tightener does not require a special handle (17mm socket wrench is best; 11/16" can be used). All parts are tested to high quality standards. This is not one of the "cheap" imitations and they are much more resistant to corrosion.

BARBED STAPLES

Barbed Staples, sliced point 8 gauge class 3 zinc coated. Stronger than other barbed staples on the market so they won't bend as easily in harder wood posts and sized to fit tube insulators better. Choice of 1.8" and 1.2" lengths, now in 50 lbs plastic buckets or 8 lbs handy packs.

Use

Class 3 Staples with all wire fences on new treated posts. Only

stainless steel or the best coated fasteners available are now recommended

for all new construction in contact with pressure treated woods.

A300 Spring-Clip™ Tightener

A300 Spring-Clip™ Tightener & A220 Superlife™ Spring

Normal spring tension is 200-250# & 7 1/2-7 1/4" coil length) in electric fences and 250-300# (7 1/4-6 3/4") in 8 or 10 strand fences.

A "must have" for use on new treated posts with the more corrosive chemical treatment.